PILOTS

Exploring Smarter Pathways

These pilots are more than experiments — they are steps toward a shared future where intelligence fuels progress across health, robotics, energy, and manufacturing.

Energy Pilot

Empowering Smarter Energy Management

Pilot Overview

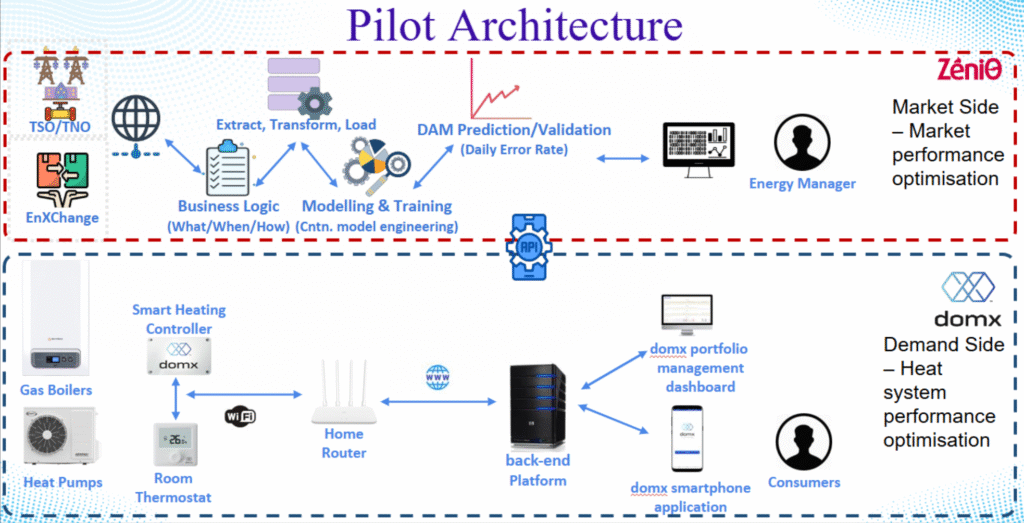

The AI-DAPT Energy Pilot envisages a transformative shift in residential heating and energy market participation by integrating AI-driven demand-side management and predictive analytics. The pilot deploys smart heating systems—developed by DOMX—and advanced market forecasting tools from energy provider ZENITH. The ultimate goal is to reduce energy consumption, cut costs and enhance grid flexibility by empowering consumers with intelligent, adaptive control of their heating systems.

Problem Description

Traditional space heating systems often operate inefficiently, relying on fixed schedules or manual controls, leading to unnecessary energy use and higher costs. Moreover, consumers typically lack access to actionable insights about energy prices and consumption patterns. At the supplier level, unpredictable demand and price fluctuations create challenges in balancing supply, procurement and operational efficiency. The Energy Pilot aspires to tackle both sides of this equation—optimising heating at the household level, while enabling suppliers to make smarter market decisions.

Stakeholders

- Residential Users: Households participating in the pilot benefit from energy savings, improved comfort and control of heating systems via a smartphone app.

- Technology Providers: DOMX provides edge controllers and cloud-based energy management systems, enabling smart heating optimisation.

- Energy Suppliers: ZENITH gains from accurate day-ahead electricity forecasts, enhancing procurement and load balancing.

- Future Enablers: Regulators, Energy Service Companies (ESCOs), research centres and AI developers are positioned to monitor pilot outcomes for energy policy alignment and build on AI-DAPT outcomes for scalable energy solutions.

Insights on Data

The pilot integrates real-time and historical data from various sources:

- Indoor and outdoor temperature sensors, heating system parameters and user comfort settings.

- Market-level data such as electricity load, renewable energy forecasts, and market transactions.

- Predictive models powered by AI forecast both electricity prices and demand with high accuracy.

These datasets will feed into AI-DAPT pipelines for model training, evaluation and deployment. Explainable AI and hybrid science-guided models ensure transparent, adaptive learning that align energy consumption with market conditions.

Conceptual Pipeline Architecture

What Do We Get from AI-DAPT

AI-DAPT can provide the backbone for smarter, scalable and more efficient energy systems:

- Reduced Forecasting Errors: AI models aim to cut price and demand prediction errors by a significant proportion.

- Energy Efficiency: AI-based smart heating control will reduce household energy use and costs while maintaining comfort.

- Demand Flexibility: AI load shifting pipelines driven price signals supports grid stability and peak load reduction.

- Trustworthy AI: Explainability, continuous learning and privacy-preserving mechanisms ensure responsible AI deployment.

- Scalable Innovation: A modular AI framework can enable replication and expansion to other regions and energy applications.

By integrating AI into the heart of energy consumption and market forecasting, the Energy Pilot lays the foundation for a more intelligent and user-centric energy future.

Manufacturing

Pilot

Optimizing Maintenance Operations in the Aviation Industry

Pilot Overview

The AI-DAPT Manufacturing Pilot addresses the aviation industry’s critical need for safe, efficient, and compliant handling of aircraft components by introducing AI-powered predictive maintenance for hoisting equipment. The pilot builds on SmartMaintain infrastructure, combining IoT-enabled data capture and adaptive workforce management to optimize maintenance processes and resource allocation. By shifting from reactive to proactive maintenance strategies, the pilot aims to reduce costs and downtime, improve safety, and enhance operational flexibility for both manufacturers and service providers in aviation.

Problem Description

Current maintenance practices for aviation manufacturing equipment are largely based on rigid annual inspections, the availability of certified specialists, and reactive repair strategies.

However, these processes face inefficiencies such as delays caused by distributed supply chains, lengthy spare part procurement, and errors in manual data collection.

As a result, they can lead to unnecessary costs, extended lead times, reduced customer satisfaction, and increased risks — including, in the worst case, production delays due to the unavailability of hoisting equipment.

The Manufacturing Pilot introduces AI-driven maintenance solutions to overcome these barriers:

- Improved data quality through transparent and automated handling of inconsistencies

- Predictive analytics to forecast maintenance needs, specifically possible disturbances

- Sensor-based data collection to ensure accurate, real-time equipment monitoring

- Automated scheduling and resource optimization to align technician availability and spare parts logistics with actual operational demand.

This data-driven approach promises to streamline maintenance operations, cut costs, and ensure regulatory compliance while meeting the aviation sector’s high safety and quality standards.

Stakeholders

Aviation Manufacturers:

White-collar staff plan and coordinate maintenance while ensuring compliance with regulatory frameworks; operators (blue-collar) use equipment daily and report faults.

Maintenance Service Providers:

- Technicians perform inspections and repairs on- and off-site.

- Coordinating Operators (Back Office) manage scheduling, compliance, and spare parts procurement.

- Logistics Staff ensure timely pick-up, delivery, and availability of hoisting equipment.

Suppliers & Tool Manufacturers: Provide spare parts and maintenance services.

Future Enablers: Regulators, AI developers, and research centers monitor pilot outcomes for alignment with industry standards and scalable innovation.

Insights on Data

The pilot leverages both legacy ERP-based systems (SmartMaintain) and IoT-enabled real-time monitoring:

- Equipment Data: Categories, specifications, condition history of hoisting tools.

- Maintenance Process Data: Planned inspections, unplanned interventions, technician activities, logistics flows, and compliance records.

- Sensor & IoT Data: Automated tracking of equipment usage patterns, wear indicators, and environmental conditions via Commercial Off-The-Shelf (COTS) components.

- Workforce & Logistics Data: Availability of certified technicians, spare parts inventories, and transportation schedules.

AI-DAPT’s explainable, hybrid AI models integrate these datasets into predictive maintenance pipelines, enabling anomaly detection, maintenance effort forecasting, and adaptive workforce scheduling.

Conceptual Pipeline Architecture

Data from the manufacturer’s ecosystem is securely pseudonymized into a “shadow environment” for analysis by the service provider. This ensures privacy, regulatory compliance, and scalable integration across operational sites.

What Do We Get from AI-DAPT

AI-DAPT’s Manufacturing Pilot brings measurable benefits for aviation maintenance operations:

- Failure Prediction & Reduced Downtime: Anticipates required maintenance activities / spare parts and provides further insights to prevent costly production delays.

- Workforce Optimization: AI-driven scheduling ensures the right technician is available at the right time, reducing bottlenecks.

- Spare Parts Efficiency: Predictive planning improves inventory management and logistics, reducing costs through leaner stock levels and minimizing delays caused by missing components.

- Safety & Compliance Assurance: Reliable, high-quality data and explainable AI minimize regulatory risks and enhance traceability.

- Scalable & Flexible Maintenance Models: Modular AI pipelines support diverse equipment types, global sites, and evolving regulations.

By embedding AI-powered predictive analytics into aviation manufacturing, the Manufacturing Pilot establishes a foundation for safer, smarter, and more efficient industrial maintenance operations.

Robotics

Pilot

Enabling Human-Centered Industrial Operations through Cognitive Ergonomics

Pilot Overview

AI-DAPT’s Robotics & Cognitive Ergonomics demonstrator introduces a new paradigm in industrial automation, focused on optimizing operator productivity and safety through the integration of real-time biometric and environmental data. The pilot is structured around two complementary scenarios: the first (MADE) involves robot-assisted visual quality control and 3D vision systems, while the second (Intellimech) focuses on mental state monitoring to prevent cognitive overload in dynamic environments. Both scenarios leverage adaptive and explainable AI pipelines to improve operational efficiency and worker well-being.

Problem Description

In industrial settings, operators are often exposed to high cognitive loads and complex environmental conditions that can compromise safety and work quality. In the first scenario, the difficulty in quickly and accurately detecting visual defects limits productivity and increases the risk of errors. In the second scenario, the lack of tools to monitor operators’ mental state prevents timely interventions to avoid stressful or inattentive situations. The Robotics Demonstrator addresses these challenges through the use of wearable and environmental sensors, which provide data for training and deploying predictive AI models, enabling truly human-centered automation.

Stakeholders

- Industrial Workers: benefit from a safer and more productive work environment thanks to continuous monitoring of their physical and mental state and automated decision-making support.

- User Companies: obtain tangible benefits in terms of increased operator productivity and, above all, improved workplace safety, resulting in the reduction in the number of accidents.

- Intellimech: as a technology provider and research partner, it benefits from the satisfaction of the companies involved, consolidating its role as an enabler of advanced AI solutions for industry. This also represents the opportunity to consolidate its own expertise and competences.

- MADE: As a technological research center on human-centered manufacturing, it aims to transfer the results and knowledge gained to the industrial world.

- Scientific Community and Applied Research: the demonstrator provides a concrete and replicable use case for the application of artificial intelligence models in cognitive ergonomics, contributing to the advancement of research and the validation of innovative approaches in real-world contexts.

Insights on Data

The Robotics & Cognitive Ergonomics demonstrator integrates a variety of biometric and environmental data, collected in two distinct scenarios that reflect complementary operational and technological needs.

Scenario 1 – Assisted Visual Inspection (MADE)

In this context, the operator works at a fixed station for the visual and manual inspection of mechanical components. The data collected includes:

- Environmental signals from fixed sensors, such as particulate matter, gas concentration, temperature, and noise, useful for assessing ergonomic and safety conditions.

- Biometric data collected via smartwatches (e.g., heart rate) and thermal imaging cameras (body temperature), which help monitor the operator’s mental state during the activity.

Scenario 2 – Maintenance in Dynamic Environments (Intellimech)

This scenario involves high-mobility activities, also in potentially hazardous environments. The data collected consists primarily of physiological signals acquired by wearable devices such as Empatica Embrace Plus and Hexoskin, which detect parameters such as heart rate, electrodermal activity (EDA), and respiration. This data allows for a real-time estimation of the operator’s mental state, with the aim of preventing cognitive overload and improving operational safety.

In both scenarios, data are analyzed and processed within the AI-DAPT platform. Data collection occurs both in the laboratory and in the field, using dedicated local infrastructures, while the platform manages the subsequent harmonization, analysis, and processing through modular pipelines. The models are updated periodically to ensure adaptability and robustness to operational conditions and the profiles of the operators involved.

Conceptual Pipeline Architecture

The AI-DAPT Robotics & Cognitive Ergonomics demonstrator is based on a modular architecture composed of four main pipelines, common to both application scenarios. These pipelines manage the entire lifecycle of AI data and models, ensuring flexibility, adaptability, and methodological consistency:

- Data Analysis Pipeline: raw data collected from environmental and biometric sensors undergoes a pre-processing phase that includes missing values management, filtering, artifact removal, and normalization. Exploratory analysis and signal quality assessment allow us to identify relevant patterns and anomalies, providing the basis for subsequent phases.

- Feature Selection Pipeline: after feature extraction, importance-based selection techniques (XAI) and correlation are applied, with the aim of reducing dimensionality and improving the robustness of models to noise. The selected features derive from temporal aggregations, signal decompositions, and, in the case of Intellimech, also from mental state assessments (e.g., stress, inattention) based on specific scientific knowledge.

- Model Training Pipeline: the processed data is divided into training and validation sets. The AI models, possibly hybrid, are trained and optimized to detect critical conditions such as visual impairment or cognitive overload. The labels used to train the supervised models can be derived from self-assessment questionnaires of mental state (e.g., stress, inattention) or from assessments based on domain-specific knowledge. The pipeline supports periodic fine-tuning based on operational feedback and new data collection sessions.

- Model Testing & Analysis Pipeline: the models are tested on real, unlabeled data, with automatic prediction generation and operator feedback collection (Human-in-the-Loop). The pipeline includes tools for performance analysis, the detection of bias and drift using XAI techniques (e.g., fairness analysis), and the possible generation of synthetic data to improve generalization.

What Do We Get from AI-DAPT

The AI-DAPT project offers the Robotics & Cognitive Ergonomics demonstrator a set of tools and infrastructure that go beyond the capabilities of traditional in-house AI development. The following are the main benefits AI-DAPT enables:

- Shared and interoperable infrastructure: AI-DAPT provides a platform that enables simplified integration of heterogeneous devices, scalable solutions, and reusable models in different contexts.

- Continuous and data-centric data management: unlike a traditional approach based on static datasets, AI-DAPT enables the continuous collection and updating of biometric and environmental data, with modular pipelines for harmonization, analysis, and processing.

- Multidisciplinary validation and technology transfer: the demonstrator benefits from collaboration with other industrial and academic partners, facilitating cross-validation of solutions and the transfer of expertise and technologies to the consortium.

- Integrated regulatory compliance: the platform is designed to comply with regulations such as the GDPR and the AI Act from the outset, with privacy-by-design mechanisms and data and model traceability.

- Reduction of technical development burden: AI-DAPT provides pre-configured tools for model orchestration and workflow automation, reducing the time and resources required for development and deployment. of AI solutions

Through the integration of advanced AI and biometric data, the AI-DAPT Robotics Demonstrator lays the foundation for safer, more efficient, and human-centered industrial automation.

Health Pilot

Transforming Personalised Healthcare

Pilot Overview

The AI-DAPT Health Pilot represents a paradigm shift towards personalised healthcare through the integration of non-invasive, AI-driven glucose monitoring solutions. This demonstrator leverages advanced machine learning algorithms coupled with wearable Photoplethysmography (PPG) sensors housed within MCS’s versatile SmarKo ecosystem. The pilot’s primary objective is to enhance diabetes management and proactive healthcare by delivering accurate, continuous glucose estimations directly to users without discomfort, thereby enabling informed, timely health decisions. A secondary objective is to be able to identidy patterns of people at risk of diabetes to have a better and non-invasive preventive solution to induce an early recognition and allow us to prevent the illness.

Problem Description

Conventional glucose monitoring predominantly depends on invasive methods, which are uncomfortable, intermittent, and inconvenient, leading to lower patient adherence and suboptimal health management. Diabetic and prediabetic individuals lack non-invasive continuous insights into glucose fluctuations, limiting their capacity for proactive healthcare management. Moreover, healthcare providers often face difficulties due to incomplete or infrequent glucose data, restricting their ability to personalise and optimise treatment strategies. The AI-DAPT Health Pilot aims to overcome these challenges through continuous, non-invasive glucose monitoring, creating a more precise and patient-centred approach to diabetes care.

Stakeholders

- Individual Users: Gain significant health benefits through improved diabetes management, continuous non-invasive monitoring, and increased personal comfort.

- Technology Providers (MCS): Supply the SmarKo® ecosystem consisting of wearable IoT devices, a phone application and the technological domain expertise to develop and research machine learning algorithms.

- Healthcare Providers and Researchers (CHARITE): Supply the patient reach to gather a high-quality dataset, enabling personalised treatment strategies and facilitating clinical research advances.

- Regulatory and Ethical Enablers: Regulatory authorities and ethics committees ensure responsible deployment of AI solutions, emphasizing compliance with GDPR and ethical standards in healthcare settings.

Insights on Data

The Health Pilot incorporates diverse, high-quality data into the AI-DAPT pipelines:

- Real-time and historical Photoplethysmography (PPG) signals from wrist-worn and finger clip sensors.

- Clinically measured glucose data that can be considered as absolute measurements utilised for robust model validation, and benchmarking.

- Clinically measured contextual metadata related to the user’s health, lifestyle and other factors that can be exploited to improve model accuracy and increase personalisation.

- Continuous Glucose Monitoring (CGM) data that has a slight increase in measurement uncertainty but a higher and automated throughput than the clinically measured glucose. This makes AI-Dapt’s data-centric approach feasible by providing a sufficient volume of glucose measurements.

Due to the sensitive nature of the data, data management practices adhere strictly to privacy-preserving and ethics-by-design principles. These data sources are integrated in the AI-DAPT platform where they are harmonised, processed and explored before being used for model training, evaluation and training.

Conceptual Pipeline Architecture

Conceptual Health Demonstrator Pipeline Architecture

AI-DAPT’s architecture integrates advanced preprocessing, feature extraction, predictive model training, validation, and deployment phases. Utilising a hybrid architecture inside our ensemble combines science-guided and AI-driven solutions such that the pipeline ensures both predictive accuracy and interpretability through Explainable AI (XAI). The automated AI pipeline lifecycle management framework ensures continuous evaluation and optimisation of models, promoting human-in-the-loop interactions to enhance clinical relevance and adaptability.

What Do We Get from AI-DAPT

AI-DAPT provides us with a platform for scalable data handling, model training and adaptive optimisation of algorithms allowing personalisation of algorithms for more accurate non-invasive glucose measurement systems.

- High Accuracy: State-of-the-art AI models achieve exceptional accuracy in non-invasive glucose estimation, significantly outperforming existing methods.

- Improved Patient Experience: Accessible continuous, comfortable, and non-invasive monitoring is projected to improve patient adherence and health management outcomes.

- Trustworthiness: The platform offers transparency and monitoring of both the data being processed, as well as the behaviour of the AI models. Such explainability and ethical compliance fosters patient trust, with robust mechanisms ensuring privacy, fairness, and regulatory compliance.

- Scalable Framework: The modular, adaptable AI-DAPT framework enables scalability across healthcare contexts and diverse patient populations, establishing a replicable model for healthcare innovation.

By integrating advanced AI into continuous glucose monitoring, the AI-DAPT Health Pilot lays a robust foundation for transformative, user-centred, and efficient diabetes management.